supplyability: 2 Set/Sets per

Weekprice: 4,600 - 49,200

Port: Qingdao ,Tianjin,Shanghai or others

Type: Vibrating Separator

Application: screening mining stone

Vibrating screen can be divided into two types: linear vibrating screen and circular vibrating screen.

The vibrating screen should be started when there are no materials on the screen and it should never be started with materials on it, and it can only be fed with materials after the screen runs stably. Before stopping it, first stop feeding and stop it after all the materials on the screen are discharged. In the working process, regularly observe the running condition of the screen, if there is abnormal movement or sound, timely stop it for examination, find out the reason and eliminate the malfunction.

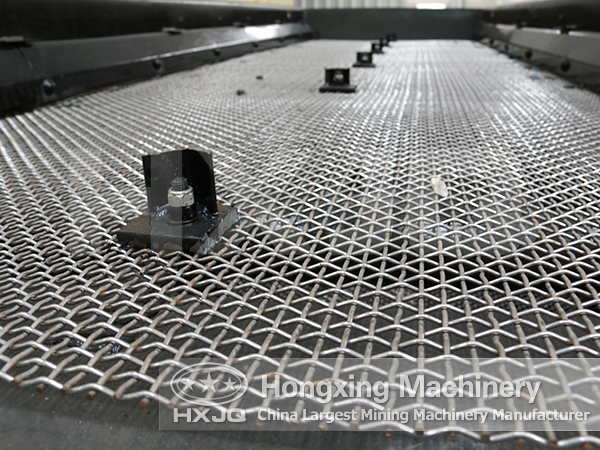

Vibrating screen is mechanical vibrating equipment driven by electric motors. Circular vibrating screen or round vibrating screen refers to the vibration sieve whose vibrator makes round movement when working.

Circular vibrating screen is new and efficient sieve shaker machine, generally with multiple layers of meshes in order to improve screening efficiency. Round vibrating screen vibrates the body driven by the eccentric shaft. Circular vibrating screen is firm and reliable and durable, and it has features of easy maintenance, low vibration noise, simple and safe operation and so on. Therefore, vibrating screens are widely used in building materials, chemicals, transportation, energy and other industries.

During the operation of sand screening machine, the two motors make synchronous reverse rotation ensure the vibration exciter generate exciting force, forcing the screen body to drive the screen to make vertical movement and make sure the periodic thrown forward in a range of the materials on the screen under the action of vibrating force, thus to complete the screening operation of the materials. The sand screening machine is suitable for sieving sand in the quarry. It also can be used for the products classification of coal, ore dressing, building material, power and chemical industry, etc.

| Model | Sieve layer |

Sieve area (m²) |

Mesh size (mm) |

Max. feeding size (mm) |

>Processing capacity (m³/h) |

Vibrating Frequency (r/min) |

Double amplitude (mm) |

Motor power (kw) |

Sieve obliquity (°) |

Sieve specification (mm) |

>Dimensions (L×W×H) (mm) |

| 2YK1225 | 2 | 6 | 4-50 | 200 | 8-60 | 800-970 | 8 | 6P 5.5KW | 20 | 1200×2500 | 2930×1860×870 |

| 3YK1225 | 3 | 9 | 4-50 | 200 | 10-70 | 800-970 | 8 | 6P 5.5KW | 20 | 1200×2500 | 3070×1860×1210 |

| 2YK1230 | 2 | 7.2 | 4-50 | 200 | 12-78 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3000 | 3430×1860×870 |

| 3YK1230 | 3 | 10.8 | 4-50 | 200 | 13-80 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3000 | 3570×1860×1210 |

| 2YK1237 | 2 | 8.88 | 4-50 | 200 | 15-86 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3700 | 4050×1860×870 |

| 3YK1237 | 3 | 13.32 | 4-50 | 200 | 16-90 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3700 | 4270×1860×1210 |

| 2YK1535 | 2 | 10.5 | 5-50 | 200 | 20-125 | 800-970 | 8 | 6P 11KW | 20 | 1500×3500 | 4120×2210×1230 |

| 3YK1535 | 3 | 15.75 | 5-50 | 200 | 21-125 | 800-970 | 8 | 6P 11KW | 20 | 1500×3500 | 4360×2210×1610 |

| 2YK1545 | 2 | 13.5 | 5-50 | 200 | 22-150 | 800-970 | 8 | 6P 11KW | 20 | 1500×4500 | 5120×2210×1230 |

| 3YK1545 | 3 | 20.25 | 5-50 | 200 | 22-150 | 800-970 | 8 | 6P 15KW | 20 | 1500×4500 | 5360×2210×1610 |

| 4YK1545 | 4 | 27 | 5-50 | 200 | 22-155 | 800-970 | 8 | 6P 15KW | 20 | 1500×4500 | 5930×2210×2060 |

| 2YK1548 | 2 | 14.4 | 5-50 | 200 | 22.5-162 | 800-970 | 8 | 6P 11KW | 20 | 1500×4800 | 5420×2210×1230 |

| 3YK1548 | 3 | 21.6 | 5-50 | 200 | 22.5-162 | 800-970 | 11 | 6P 15KW | 20 | 1500×4800 | 5660×2210×1610 |

| 4YK1548 | 4 | 28.8 | 5-50 | 200 | 22.5-162 | 800-970 | 8 | 6P 18.5KW | 20 | 1500×4800 | 6230×2210×2060 |

| 2YK1848 | 2 | 17.28 | 5-80 | 200 | 25-206 | 750 | 8 | 6P 18.5KW | 20 | 1800×4800 | 5420×2550×1420 |

| 3YK1848 | 3 | 25.92 | 5-80 | 200 | 32-276 | 750 | 8 | 6P 18.5KW | 20 | 1800×4800 | 5660×2550×1780 |

| 4YK1848 | 4 | 34.56 | 5-80 | 200 | 32-285 | 750 | 8 | 6P 22KW | 20 | 1800×4800 | 6290×2550×2160 |

| 2YK1854 | 2 | 19.44 | 5-80 | 200 | 32-312 | 800-970 | 8 | 6P 22KW | 20 | 1800×5400 | 5960×2550×1420 |

| 3YK1854 | 3 | 29.16 | 5-80 | 200 | 32-312 | 800-970 | 8 | 6P 22KW | 20 | 1800×5400 | 6260×2550×1780 |

| 4YK1854 | 4 | 38.88 | 5-80 | 200 | 32-336 | 800-970 | 8 | 6P 22KW | 20 | 1800×5400 | 6830×2550×2160 |

| 2YK2160 | 2 | 25.2 | 5-100 | 200 | 50-475 | 970 | 8 | 6P 30KW | 20 | 2100×6000 | 6720×2840×1530 |

| 3YK2160 | 3 | 37.8 | 5-100 | 200 | 50-475 | 970 | 8 | 6P 30KW | 20 | 2100×6000 | 7030×2840×1910 |

| 4YK2160 | 4 | 50.4 | 5-100 | 200 | 50-497 | 970 | 8 | 6P 37KW | 20 | 2100×6000 | 7300×2840×2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 200 | 65-550 | 970 | 8 | 6P 30KW | 20 | 2400×6000 | 7020×3140×1530 |

| 3YK2460 | 3 | 43.2 | 5-100 | 200 | 70-620 | 970 | 8 | 6P 37KW | 20 | 2400×6000 | 7300×3140×1910 |

| 4YK2460 | 4 | 57.6 | 5-100 | 200 | 80-680 | 970 | 8 | 6P 45KW | 20 | 2400×6000 | 7600×3140×2380 |

| 2YK2870 | 2 | 39.2 | 5-100 | 200 | 120-680 | 750 | 8 | 8P 22×2KW | 20 | 2800×7000 | 7600×4320×1620 |

| 3YK2870 | 3 | 58.8 | 5-100 | 200 | 180-720 | 750 | 8 | 8P 22×2KW | 20 | 2800×7000 | 7800×4320×2120 |

| 2YK3072 | 2 | 43.2 | 5-100 | 200 | 200-700 | 750 | 8 | 8P 22×2KW | 20 | 3000×7200 | 7800×4520×1750 |

| 3YK3072 | 3 | 64.8 | 5-100 | 200 | 230-800 | 750 | 8 | 8P 22×2KW | 20 | 3000×7200 | 8000×4520×2300 |